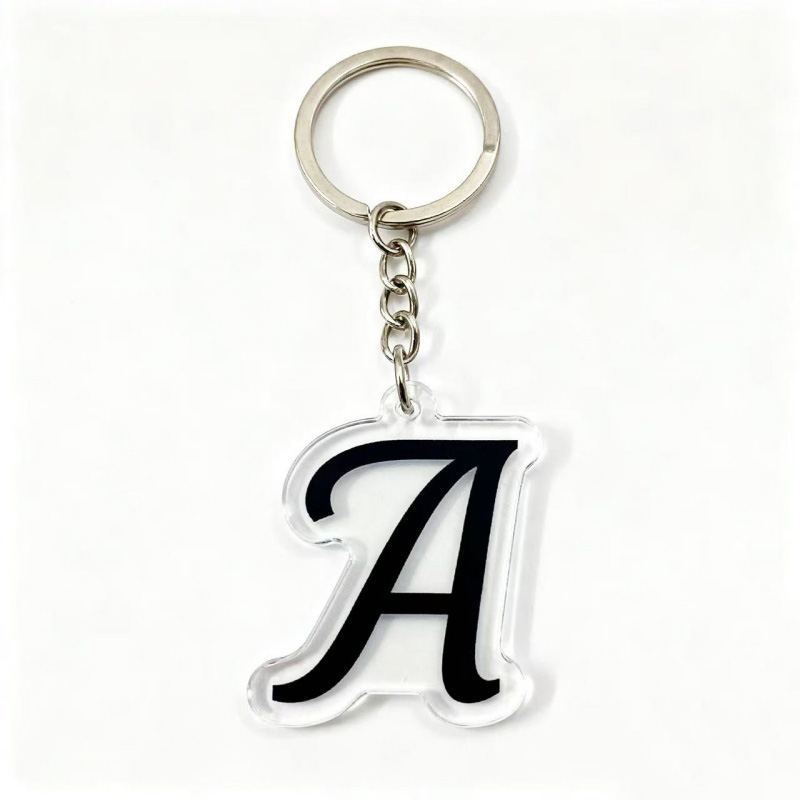

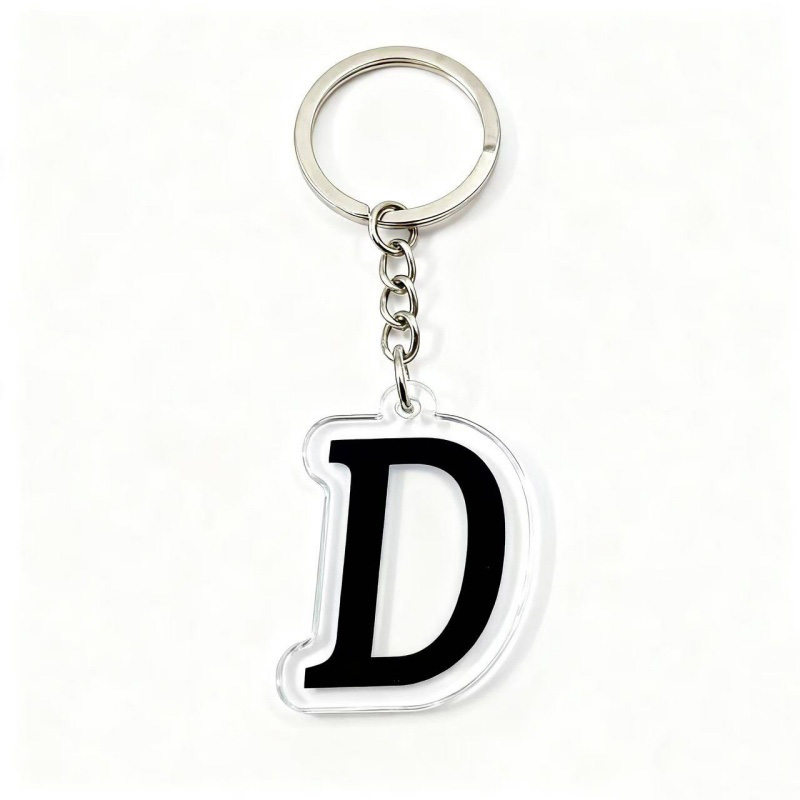

Customized Letter Acrylic Keychain

Product features and advantages

●Advantages:

▪Versatile Customization: Easy to print full-color, detailed graphics or text, suitable for personalization (gifts, souvenirs) or branding.

▪Lightweight & Safe: Lighter than glass or metal alternatives, with smooth edges that avoid scratches on fridge surfaces.

▪Durable & Long-Lasting: Resistant to scratches, fading, and daily wear, maintaining a sleek appearance for years.

▪Transparency: Showcases printed designs (photos, logos, art) with high clarity, enhancing visual appeal.

▪Cost-Effective: Affordable to produce in bulk, offering great value for promotional items or personal use.

Product Parameters

■ Material:Acrylic

■ Size:Logo shape, Customer required

■ Payment methods: telegraphic transfer, letter of credit, PayPal

| Item name | Acrylic Keychain |

| Material | Acrylic |

| Shape | Custom shape |

| Color Process | According to the PMS chart |

| One or Double-sided | |

| Packing | Poly bag, OPP bag, Bubble bag, Gift box, Custom required |

| Application | Souvenir, Gifts, Decoration, Promotion Gifts… |

- Application Scenarios:Souvenir, Gifts, Decoration, Promotion Gifts…

Process Introduction of Acrylic Keychains

Acrylic keychains are made via a streamlined workflow combining precision processing and customization. Below is the key-focused breakdown:

- Material Prep

Core material: 1-5mm extruded/cast acrylic sheets (transparent/opaque/colored).

Step: Inspect for defects (scratches, bubbles); cut into small blocks if multi-layer designs are needed.

- Design & Pattern Making

Use vector software or 3D tools to create designs (shape, logo, text).

Convert files to machine-compatible formats.

- Cutting & Shaping (2 Main Methods)

Laser Cutting (precision/intricate designs): Laser melts/vaporizes acrylic for smooth, burr-free edges; cool after cutting.

Die-Cutting (mass production/simple shapes): Hydraulic press uses metal dies to punch out shapes quickly.

- Surface Treatment (Key Aesthetics)

Engraving: Laser (frosted effect) or mechanical (3D tactile details).

Printing: UV (waterproof, high-res full color) or screen (single/multi-color logos).

Polishing (Optional): Mechanical (glossy edges) or flame (clear finish for transparent acrylic) to smooth rough edges.

- Drilling & Assembly

Drilling: Precision-drill a 3-5mm hole (for key hardware); may sync with laser cutting.

Assembly: Attach jump rings to the hole, then add split key rings/lobster clasps; bond multi-layer acrylic with clear adhesive first if needed.

- Quality Check & Packaging

Inspect for loose hardware, scratches, misprints.

Package individually (opp bags, boxes) for protection and presentation.