Production Process Modules:

ARTWORK DESIGN

Artwork is designed per your requirements. Free samples are provided for confirmation. We support multiple colors or complex craft processes.

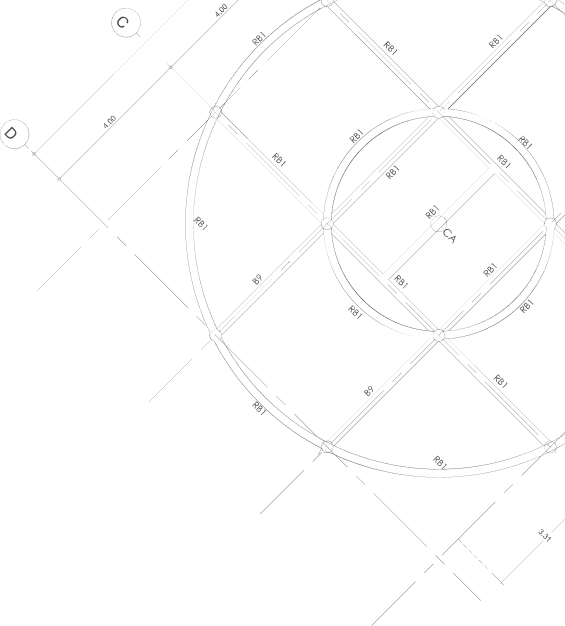

MOULD TOOLING

Short mold development cycle. We can produce metal and plastic molds as needed.

STAMPING/PRESSING/DIECASTING

We support stamping, pressing, or die-casting processes to produce lapel pins, medals, and other products.

HIGH-PRECISION PRESSURE

High-precision equipment enables the production of products with complex shapes and ensures quality.

CUTTING SHAPE

Cutting is made via laser or hydraulic cutting machines, ensuring product precision.

FIXING ATTACHMENT

Different attachments will be fixed to the products as required, such as pins, clips, etc.

POLISHING

The material surface is refined to improve texture and remove burrs.

PLATING FINISH

A variety of finishes (e.g., gold, silver) are achieved through electroplating.

COLORING

Machine coloring is applied for even color distribution and stable production. BAKING After coloring, the product is baked to cure the color and enhance durability.

QC&PACKING

All items undergo strict quality checks before packing to ensure zero defects.

SHIPPING

We handle shipping via sea or air. For large orders, delivery takes 15 days; for urgent orders, we also offer express services.

.jpg)

.jpg)